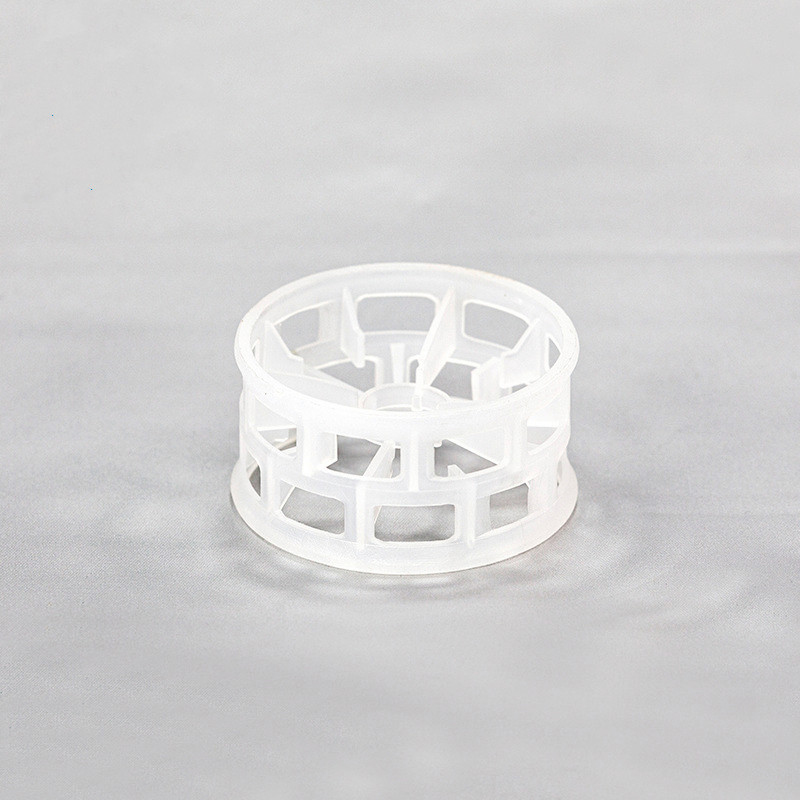

Plastic Beta Ring Tower Packing

Technical Specification of Plastic Beta Ring

|

Product name |

Plastic beta ring |

||

|

Material |

PP, PE, PVC, CPVC, RPP, PVDF and etc. |

||

|

Life span |

>3 years |

||

|

Product name |

Diameter (mm/Inch) |

Void volume % |

Packing density Kg/m3 |

|

Beta ring |

25(1”) |

94 |

53kg/m3 (3.3lb/ft3) |

|

Beta ring |

50(2”) |

94 |

54kg/m3 (3.4lb/ft3) |

|

Beta ring |

76(3”) |

96 |

38kg/m3 (2.4lb/ft3) |

|

Feature |

1. Low aspect ratio increases capacity and reduces pressure drop. The preferred vertical orientation of the packing axes allows free gas flow through the packed bed. |

||

|

Advantage |

Open structure and preferred vertical orientation inhibits fouling by allowing solids to be more easily flushed through the bed by the liquid. Low liquid hold-up minimizes column inventory and liquid residence time. |

||

|

Application |

These various plastic tower packing are widely used in petroleum and chemical, alkali chloride, gas and environmental protection industries with max. temperature of 280°. |

||

Physical & Chemical Properties of Plastic Beta Ring

Plastic tower packing can be made from heat resistant and chemical corrosion resistant plastics, including polyethylene (PE), polypropylene (PP), reinforced polypropylene (RPP), polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC), polyvinyiidene fluoride (PVDF) and Polytetrafluoroethylene (PTFE). The temperature in media ranges from 60 Degree C to 280 Degree C.

|

Performace/ Material |

PE |

PP |

RPP |

PVC |

CPVC |

PVDF |

|

Density (g/cm3) (after injection molding) |

0.98 |

0.96 |

1.2 |

1.7 |

1.8 |

1.8 |

|

Operation temp.(℃) |

90 |

>100 |

>120 |

>60 |

>90 |

>150 |

|

Chemical corrosion resistance |

GOOD |

GOOD |

GOOD |

GOOD |

GOOD |

GOOD |

|

Compression strength(Mpa) |

>6.0 |

>6.0 |

>6.0 |

>6.0 |

>6.0 |

>6.0 |

Material

Our Factory assure all tower packing made from 100% Virgin Material.

Shipment for Products

1. OCEAN SHIPPING for large volume.

2. AIR or EXPRESS TRANSPORT for sample request.

Packaging & Shipping

|

Package type |

Container load capacity |

||

|

20 GP |

40 GP |

40 HQ |

|

|

Ton bag |

20-24 m3 |

40 m3 |

48 m3 |

|

Plastic bag |

25 m3 |

54 m3 |

65 m3 |

|

Paper box |

20 m3 |

40 m3 |

40 m3 |

|

Delivery time |

Within 7 working days |

10 working days |

12 working days |