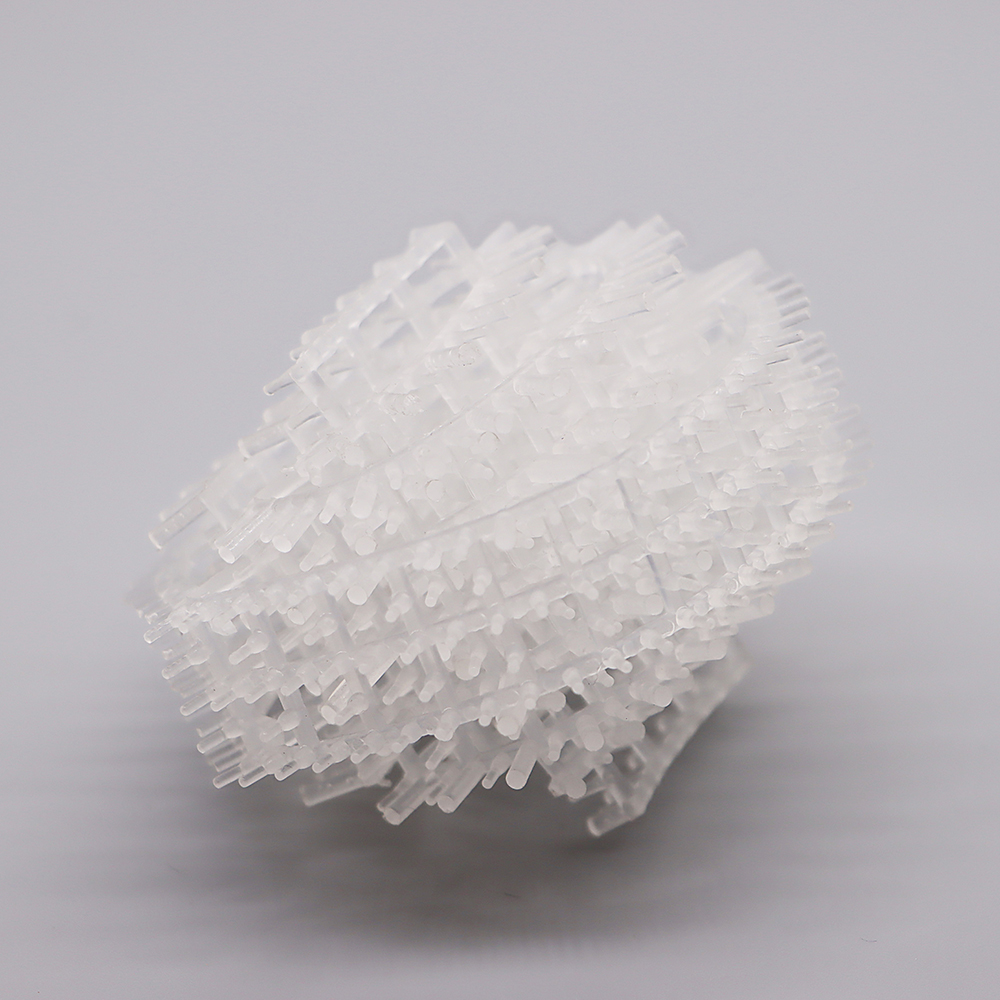

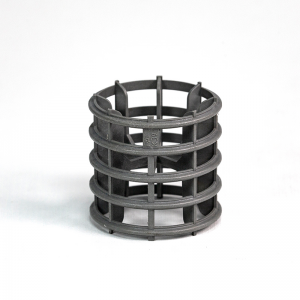

Tower Packing Water Treatment Plastic Igel ball

Technical Specification of Plastic Igel Ball

|

Product name |

Plastic igel ball |

|||

|

Material |

PP, PE, PVC, CPVC, PVDF, etc |

|||

|

Size mm |

Surface area m2/m3 |

Void volume % |

Packing density Kg/m3 |

Dry packing factorm-1 |

|

40 |

300 |

87 |

102 |

473 |

Physical & Chemical Properties of Plastic Igel Ball

Plastic tower packing can be made from heat resistant and chemical corrosion resistant plastics, including polyethylene (PE), polypropylene (PP), reinforced polypropylene (RPP), polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC), polyvinyiidene fluoride (PVDF) and Polytetrafluoroethylene(PTFE). The temperature in media ranges from 60 Degree C to 280 Degree C.

|

Performance/Material |

PE |

PP |

RPP |

PVC |

CPVC |

PVDF |

|

Density (g/cm3) (after injection molding) |

0.98 |

0.96 |

1.2 |

1.7 |

1.8 |

1.8 |

|

Operation temp.(℃) |

90 |

>100 |

>120 |

>60 |

>90 |

>150 |

|

Chemical corrosion resistance |

GOOD |

GOOD |

GOOD |

GOOD |

GOOD |

GOOD |

|

Compression strength (Mpa) |

>6.0 |

>6.0 |

>6.0 |

>6.0 |

>6.0 |

>6.0 |

|

Performance /Material |

PE |

PP |

RPP |

PVC |

CPVC |

PVDF |

|

Density (g/cm3) (after injection molding) |

0.98 |

0.96 |

1.2 |

1.7 |

1.8 |

1.8 |

|

Operation temp.(℃) |

90 |

>100 |

>120 |

>60 |

>90 |

>150 |

|

Chemical corrosion resistance |

GOOD |

GOOD |

GOOD |

GOOD |

GOOD |

GOOD |

|

Compression strength (Mpa) |

>6.0 |

>6.0 |

>6.0 |

>6.0 |

>6.0 |

>6.0 |