Plastic Tower Packing

-

Plastic Beta Ring Tower Packing

Plastic Beta Ring is made from heat resistant and chemical corrosion resistant plastics, including polypropylene (PP), polyvinyl chloride (PVC), chloridized polyvinyl chloride (CPVC) and polyvinylidene fluoride (PVDF). It has features such as large void space, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific gravity, high mass transfer efficiency and so on, and the application temperature in media ranges from 60 to 280℃. For these reasons it is widely used in the packing towers in petroleum industry, chemical industry, alkali-Chloride industry, coal gas industry and environmental protection, etc.

-

Plastic Ralu Ring Tower Packing

Plastic Ralu Ring is an improved pall ring, their open structure ensures a regular flow through the packed bed resulting in a minimal pressure drop.

Plastic ralu rings are made of heat resistant and chemical corrosion resistant plastics including PP, PE, RPP, PVC, CPVC and PVDF.

Plastic Ralu Rings are featured with high free volume, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific gravity, high mass transfer efficiency and so on, and the application temperature in media ranges from 60°C to 280°C.

Plastic ralu ring is widely apply in all kinds of separation, absorption and desorption device, atmospheric and vacuum distillation device, decarburization and desulfurization system, ethylbenzene, iso-octane and toluene separation.

-

Plastic VSP Ring Chemical Packing

The characteristics of plastic VSP-pack ring have large void rate, low pressure drop and low height of mass transfer unit, high extensive point, full contact of gas and liquid, low specific weight and high mass transfer efficiency. It is widely used in the packing towers, petroleum industry, chemical industry, alkali-Chloride industry, coal gas industry and environmental protection and etc.

VSP plastic Inner Arc packing: VSP ring also named Mella ring, VSP ring means very special packing in foreign country meaning very excellent packing. It has many advantages such as low pressure drop, large throughout, high efficiency, high operating elasticity, perfect strength.

VSP Ring has rational symmetry, excellent inner structure and large free space. Compared with Pall ring, its flux effiency is increase 15-30%, its pressure drop is reduce 20-30%. it is recognized the excellent random packing in tower packing.

-

Plastic Cascade Mini Ring Chemical Packing

Plastic Cascade Mini Ring is made from heat resistant and chemical corrosion resistant plastics, including polyethylene (PE), polypropylene (PP), reinforced polypropylene (RPP), polyvinyl chloride (PVC), chloridized polyvinyl chloride (CPVC) and polyvinylidene fluoride (PVDF).

Plastic Cascade Mini Ring:

It was developed by British Company MTL Ltd, which also called CMR. It has not only change traditonal equal length and diameter, but also cone-shaped flanging at one edge. This special structure has shorten distance which gas passing through wall’s out surface, but also reduced the resistance when air passing through bed layer and increased voidage. -

Plastic Pentagon Ring tower packing

Plastic pentagon packing is an excellent packing. Based on this product’s structure analysis, funnelled hollow out design speeds up liquid’s velocity so as to improve Gas & liquid separation efficiency. Ring wall’s large area opening hole overcomes big area blocking. Five pieces of horizontal bar which bend toward the centers forms more bigger surface for gas & liquid’s contacting. More obviously feature is five pieces of down warded rods evenly distribution. This distribution will promote liquid drop to form big droplet. Finally, it is recognized high efficiency random packing used in separation.

-

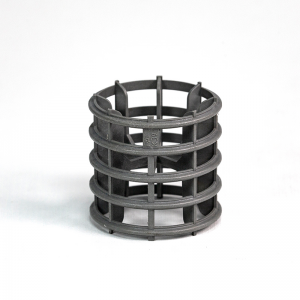

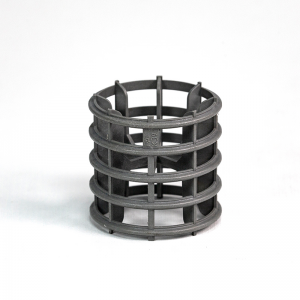

High Performance Tower Packing Plastic Hiflow Ring

Plastic Hiflow ring is a 3rd generation high performance tower packing which provides an optimal design of high mechanical stability, void fraction and superior mass transfer performance. The grid structure guarantees its opening pore ratio exceed 50% and bed void fraction is higher than same size’s pall ring. In addition, large fluid flux guarantee its pressure drop per square meter lower 45% than pall ring. Vertical bar staggered distribution and reinforced horizonal stripe largely improve its rigidity and strength. It has features such as high free volume, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific gravity, high mass transfer efficiency and so on.

-

Plastic Super Raschig Ring tower packing

Plastic super raschig ring is one kind of random packing design by Zhongtai’S research and development team, it with large surface area, and high free volume, low pressure drop, low mass-transfer unit height, uniform gas-liquid contact, small specific gravity, high mass transfer efficiency and so on. It’s the development packing design based on plastic raschig ring and pall ring.

-

Plastic Flat Ring tower packing

Plastic Flat ring has a small ratio of height to diameter, about 1:3. Due to its structure’s change, effectively reducing the filler layer axial back mixing so as to improve the liquid-liquid mass transfer efficiency between two phases. Moreover, it is suitable for such packing liquid-liquid mass transfer of the extraction process. The Flat ring packing is similar to ring of the Cascade Mini Ring on the structure, but there are no top turn ups, guarantee packing unify orientation when piling up, increase pile density, make packing layer liquid distribute further more even improved inside separate.

-

PP Plastic snowflake ring random tower packing

Plastic snowflake ring is made from heat resistant and chemical corrosion resistant plastics, including polyethylene (PE), polypropylene (PP), reinforced polypropylene (RPP), polyvinyl chloride (PVC), chloridized polyvinyl chloride (CPVC) and polyvinylidene fluoride (PVDF). It has features such as high free volume, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific gravity, high mass transfer efficiency and so on, and the application temperature in media ranges from 60 to 150. For these reasons it is widely used in the packing towers in petroleum industry, chemical industry, alkali-Chloride industry, coal gas industry and environmental protection, etc.

-

Plastic Q-pack Scrubber Packing

Plastic Q-pack suitable for use in a lot of different potable water treatment processes, such as:

Biological treatment

Physical filtration

Pre-treatment for desalination

Drinking water treatment

Q-pack’s large pore volumes and surface areas make it an ideal media for biological treatment of drinking water. Bio film processes are excellent for treating raw water containing ammonia, manganese, iron etc. In conventional filtration processes Q-pack can be used in different ways. In dual media filters Q-pack can be used in combination with sand. Tests have shown that Q-pack operates as well as or better than traditional filter media in these types of filters. Q-pack can not only be used in traditional drinking water treatment, but also in treatment of saline water. In desalination plants one of the most important parts is the pre-treatment process. Q-pack is an excellent filter media for use in pre-treatment filters in desalination plants. -

Tower Packing Water Treatment Plastic Igel ball

Plastic Igel ball is a normal biological filter, its excellent performance and long-term improvement. Our igel ball is made of plastic, so it have light weight and can float on the water, the shape is ball. Its characterized by small water resistance, good ventilation, most of igel ball have diversion design, such as deflector, diversion channel, the water can be evenly distributed meanwhile increased water flow.

It’s better to gas exchange, can increase dissolved oxygen content and remove H2S and CO2.

It is be used in pond and aquarium.Features of Plastic Igel Ball

Adopting environmental plastic material with many specifications. All bio balls have wide surfaces for nitrifying bacteria to grow. It can help to establish the most complete and balanced system for biological filtration and can be used in both fresh and marine water tanks filtering biologically in both sea water tanks and fresh water tanks. -

Plastic Lanpack Ring For Tower Packing

1. Our Lanpacks have achieves the impossible: significantly lower pressure drop and higher transfer efficiencies than other smaller packings. 2. Our Lanpacks has a track record of superior performance in the field. It comes in two sizes: 2.3 inches and 3.5 inches, Zhongtai have a variety of plastic materials inchluding polypropylene, polyethylene, PVDF, etc. 3. It’s the best parts in tower packing for application with high liquid loading. such as: 1). Ground water remediation by air str...