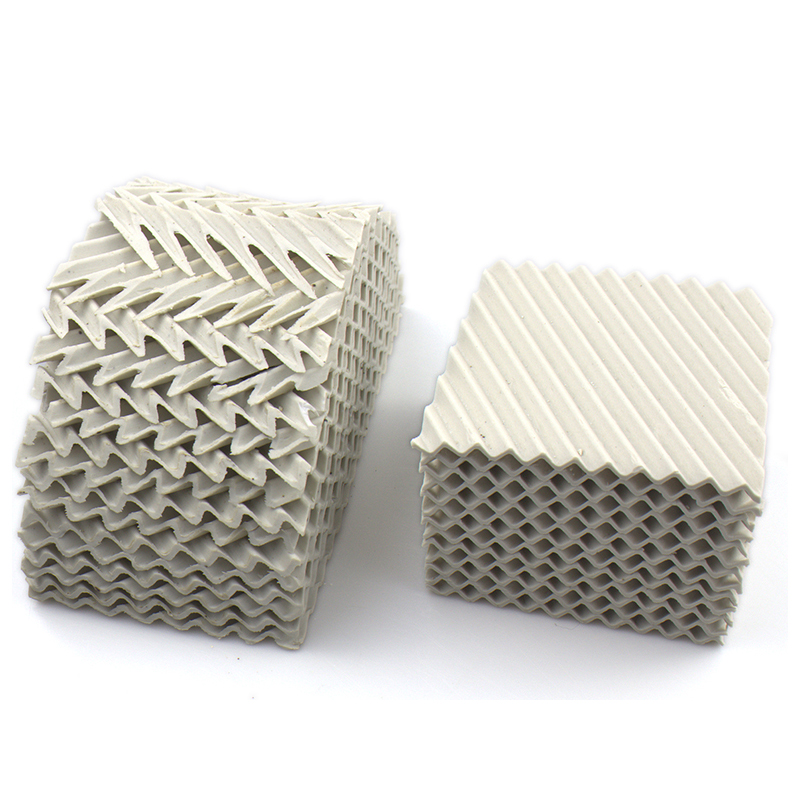

Ceramic Structured Tower Packing

Products Introduction of Ceramic Structured Packing

Because of ceramic unique structure, good hydrophilic performance, its surface can form a very thin liquid film of turbulent airflow tilt and tortuous channels can promote the air but not stop match the metal filler air can make the ceramic packing, and its corrosion resistance, high temperature resistant performance of metal filler can’t compared. Surface structure has good wetting property, can accelerate liquid flow, make the packing delay fluid volume to a minimum. To reduce the chance of overheating, aggregation, and coking. This product is made of high quality chemical porcelain clay raw material processing and become, resistant to high temperature and high pressure, good chemical stability and high strength, is an ideal carrier to support various types of catalysts.

Chemical Analysis of Ceramic Structured Packing

| Composition | Value |

| SiO2 | ≥72% |

| Fe2O3 | ≤0.5% |

| CaO | ≤1.0% |

| Al2O3 | ≥23% |

| MgO | ≤1.0% |

| Other | 2% |

Physical Property of Ceramic Structured Packing

| Index | Value |

| Specific gravity(g/cm3) | 2.5 |

| Water absorption (wt%) | ≤0.5 |

| Acid resistance (wt%) | ≥99.5 |

| Loss in burn (wt%) | ≤5.0 |

| Max. operating temp.(℃) | 800 |

| Crush strength (Mpa) | ≥130 |

| Moh’s hardness(Scale) | ≥7 |

Technical Specification of Ceramic Structured Packing

| Spec. | Specific surface (m2/m3) | Bulk density (kg/ m3) | Void ratio (%) | Obl. angle | Pressure drop (mm Hg/m) | Theo. plate (m-1) | Hydraulic diameter (mm) | Liquid load (m3/m2h) | Max. factor m/s (Kg/m3)-1 |

| 125Y | 125 | 320 | 90 | 45 | 1.8 | 1.8 | 28 | 0.2-100 | 3.0 |

| 250Y | 250 | 420 | 80 | 45 | 2 | 2.5 | 12 | 0.2-100 | 2.6 |

| 350Y | 350 | 470 | 78 | 45 | 2.5 | 2.8 | 10 | 0.2-100 | 2.5 |

| 450Y | 450 | 520 | 72 | 45 | 4 | 4 | 7 | 0.2-100 | 1.8 |

| 550Y | 550 | 620 | 74 | 45 | 5.5 | 5-6 | 6 | 0.18-100 | 1.4 |

| 700Y | 700 | 650 | 72 | 45 | 6 | 7 | 5 | 0.15-100 | 1.3 |