Honeycomb Ceramic

-

RTO Heat Exchange Honeycomb Ceramic

Regenerative Thermal/Catalytic Oxidizer (RTO/RCO) are used to destroy Hazardous Air Pollutants (HAPs), Volatile Organic Compounds (VOCs) and odorous emissions etc, which are extensively applied in the fields of Automotive paint, Chemical industry, Electronic & Electric Manufacturing industry, Contact Combustion System, and so on. Ceramic Honeycomb is specified as structured regenerative media of RTO/RCO.

-

Catalyst carrier cordierite honeycomb ceramics for DOC

Ceramic honeycomb substrate (catalyst monolith) is a new kind of industrial ceramic product, as a catalyst carrier which are widely used in automobile emissions purifying system and industrial exhaust gas treatment system.

-

Infrared honeycomb ceramic plate for BBQ

Outstanding Strength Uniform radiant burning

Excellent thermal shock resistance Save up to 30~50% energy cost Burn without flame.

Quality raw materials.

Ceramic Substrate/ honeycomb in cordierite, alumina, mullite

Many sizes available.

Our regular size is 132*92*13mm But we can produce different sizes according to the customer’s oven, fully energy-saving and efficient combustion. -

Cordierite DPF Honeycomb Ceramic

Cordierite Diesel Particulate Filter(DPF)

The most common filter is made of cordierite. Cordierite filters provide excellent filtration efficiency, are relatively

inexpensive (comparison with Sic wall flow filter). The major drawback is that cordierite has a relatively low melting point. -

Thermal Storage Rto/Rco Honeycomb Ceramic as Catalytic Converter for Heat Recovery

It is a highly efficient organic waste gas treatment equipment. Its working principle is to heat the organic waste gas to above 760 degrees Celsius to oxidize and decompose the volatile organic compounds (VOCs) in the waste gas into carbon dioxide and water. The heat generated by the oxidation process is stored in a special ceramic heat storage body, which heats up the heat storage body to “storage heat”. The heat stored in the ceramic heat storage body is used to preheat the subsequent organic waste gas. This process is the “heat release” process of the ceramic heat storage body, thereby saving fuel consumption in the waste gas heating process.

-

Universal Direct Fit Catalytic Converter | EPA Compliant Replacement with Ceramic Honeycomb Core

Hot Sale Welding Universal Catalytic Converter With Ceramic Honeycomb Catalyst Three-way Catalytic Converter Features: 1. We supply worldwide: North American, South American, Europe, Australia, Southeast Asian and Mid-East 2. Professional manufacturer of catalyst coating 3. Sample: According to your request, sampling time 3-7day. For existing samples, sampling time 1-2days 4. OEM accepted: We can produce according to your request. Performace 1. Light off emperature: CO≤210℃ HC≤230℃ ... -

400 CPSI Cordierite Heater Plate | High-Temp Infrared Industrial Heater

Product Overview The Ceramic Honeycomb Plate is a high-performance industrial component featuring a porous cellular structure. It is renowned for its exceptional thermal conductivity, high-temperature stability, and corrosion resistance. Manufactured from advanced ceramic materials such as cordierite and mullite, it is precision-formed into a honeycomb configuration that significantly increases the effective surface area. This design enables efficient heat transfer and uni... -

Cordierite-Mullite Honeycomb for RTO/RCO | Advanced Thermal Storage Media

Mullite-Cordierite Honeycomb Ceramic for RTO/RCO Systems As the core component of High Temperature Air Combustion (HTAC) systems, our honeycomb ceramic thermal storage media delivers exceptional performance through its unique material properties. Engineered with low thermal expansion coefficient, high specific surface area, excellent thermal stability, and superior corrosion resistance, this advanced ceramic solution ensures reliable operation in demandi... -

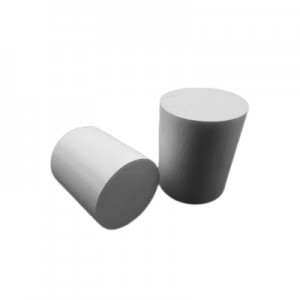

Metal Honeycomb Catalyst Substrate | Ceramic-Coated Monolithic Structure

Product Overview The Round Honeycomb Ceramic Carrier & Thermal Storage Unit delivers high efficiency and energy savings for industrial heat recovery and environmental applications. Its circular geometry enables simple installation and uniform gas flow, while the honeycomb configuration greatly expands the functional surface area, boosting heat and mass transfer performance. This product is essential for cutting energy use, raising productivity...