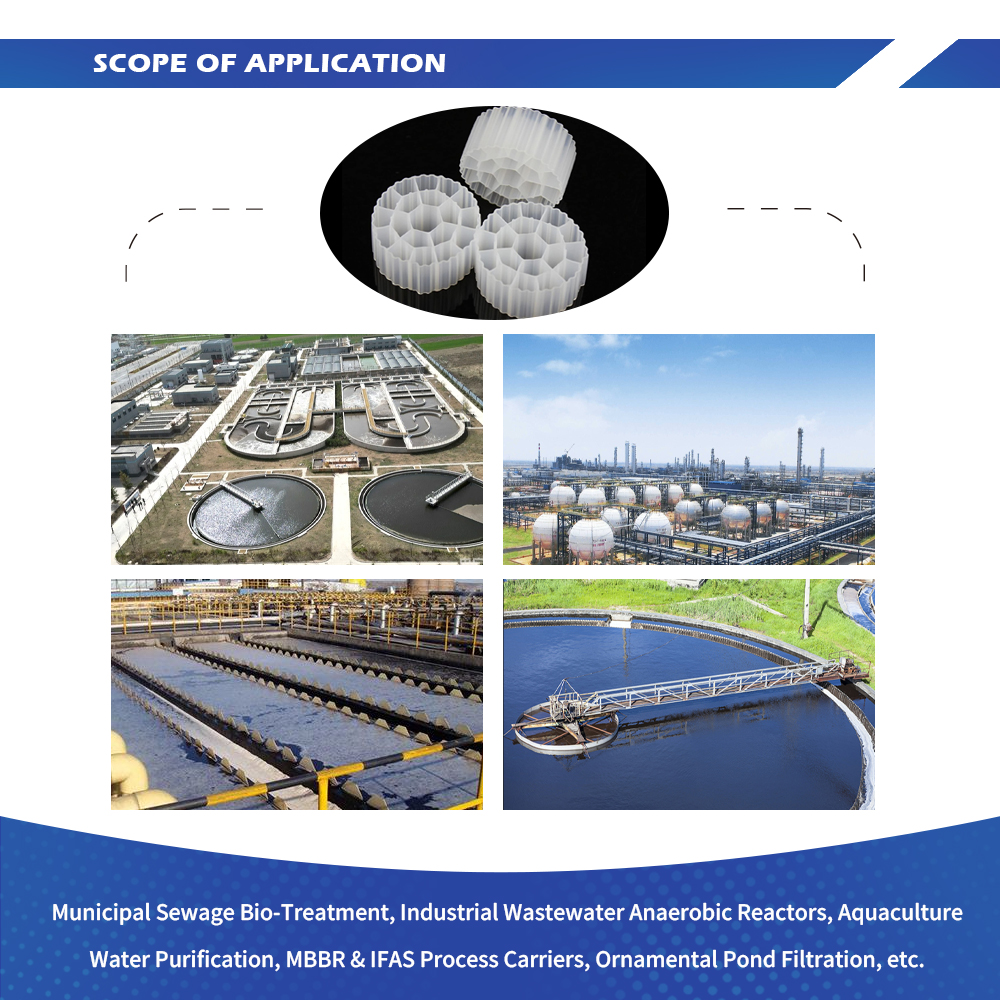

HDPE MBBR Media Biochips (K1, K3, K5) – Plastic Bio Filter Media for Sewage and Wastewater Treatment Plants

HDPE K1 K3 K5 Biochips Mbbr Media Plastic Bio Media Filter Mbbr Plants For Sewage Treatment

The moving bed biofilm reactor (MBBR) is an efficient biofilm technology, which combines the advantages of traditional fluidized bed.

The MBBR process adds a certain amount of suspended filler (biofilm carrier) to the reactor, and in the protected area of the

filler, different microorganisms (from bacteria to ciliates to rotifers) concentrate on the biofilm. Some anaerobic or aerobic

bacteria are grown inside the carrier, while aerobic bacteria are grown outside. Each carrier is a micro-reactor, which ensures

extensive and frequent contact between waste water and biofilms on the carrier, either through blast aeration in the aerobic

treatment system or stirring in the anaerobic treatment system. While improving the mass transfer efficiency of the system, the

renewal of biofilm microorganisms should be strengthened to maintain and improve the activity of biofilm. The suspended carrier

and the original activated sludge form a more complex complex ecosystem and the biofilm attached to the carrier greatly increases

the active biomass in the reactor. Under the joint action of suspended activated sludge and biofilm on the surface of suspended

carrier, the impact load resistance capacity of the system is greatly improved, so as to improve the efficiency of sewage

treatment and stabilize the effluent quality.

HDPE K1 K3 K5 Biochips Mbbr Media Plastic Bio Media Filter Mbbr Plants For Sewage Treatment

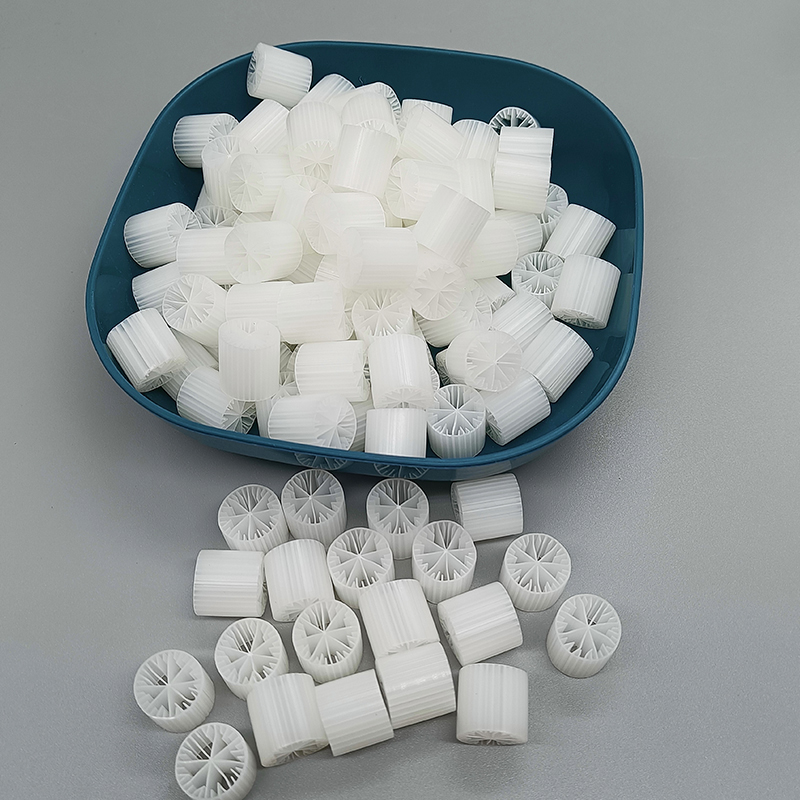

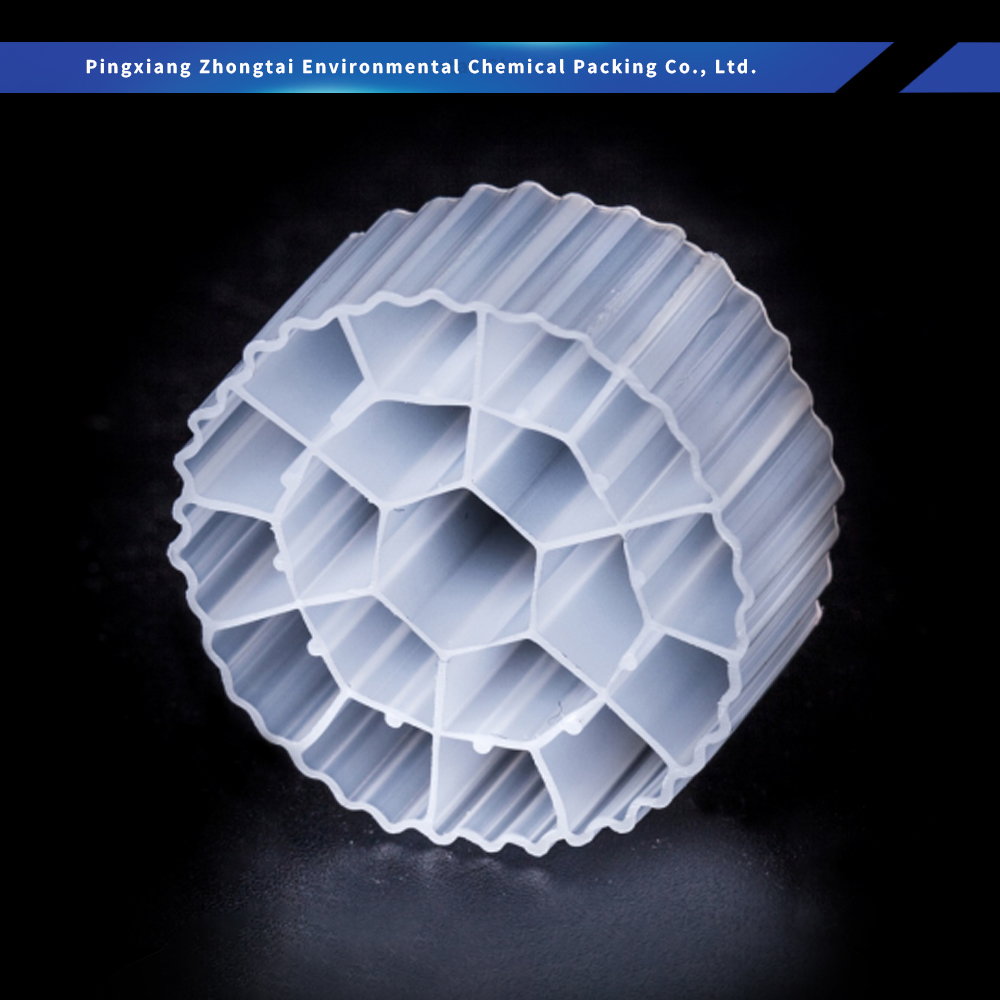

1.Special design of surface, stronger bio-film growth capacity;

2.Large specific surface area, high voidage, the more periphyton biomass;

3.Unique design of structure and shape according to hydromechanics, strong three-dimensional flow dynamics in the water;

4.Adding hydrophilic groups and other trace elements, the biofilm formation time only 3-15 days;

5.Excellent impact strength, strong gas shear capacity;

6.Without any holder, easy to cure, save energy and space.

| Model | PE01 | PE02 | PE03 | PE04 | PE05 | |

|---|---|---|---|---|---|---|

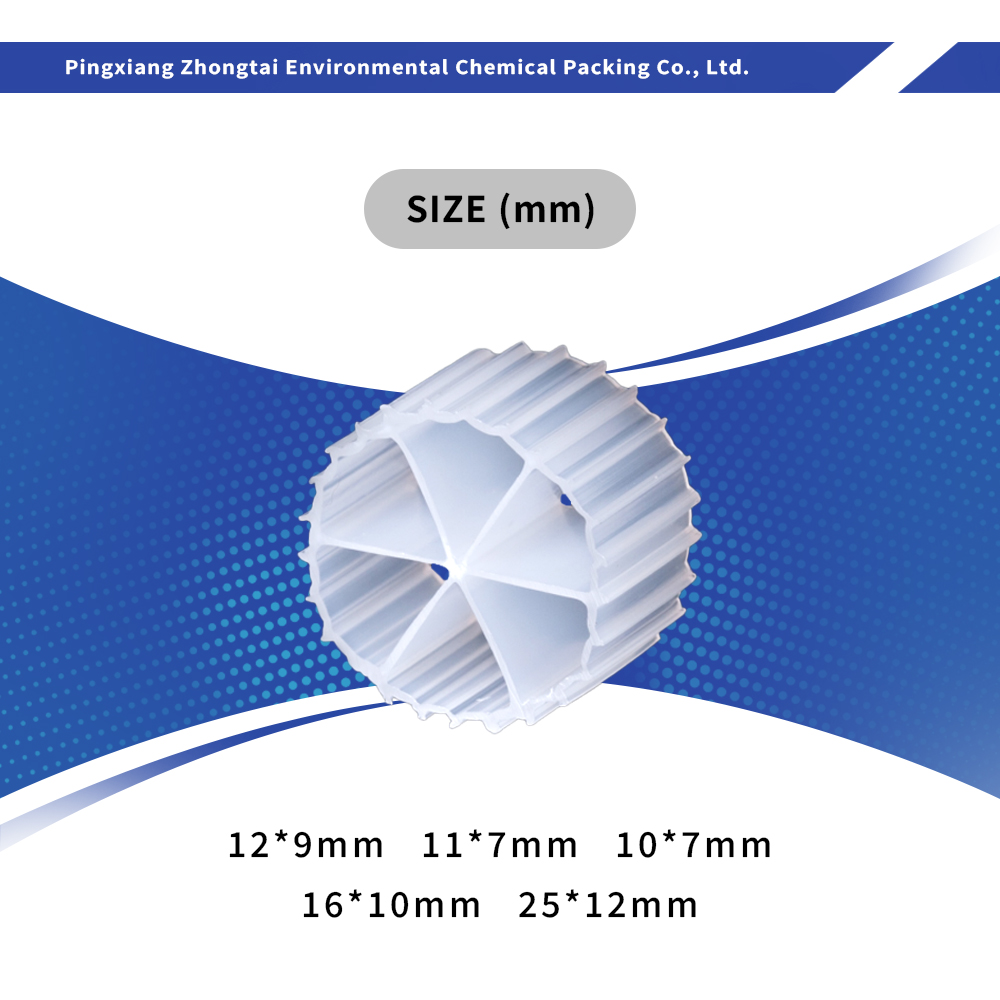

| Spec | mm | Dia 12X9mm | Dia 11X7mm | Dia 10X7mm | Dia 16X10mm | Dia 25X12 |

| Hole Numbers | pcs | 4 | 4 | 5 | 6 | 19 |

| Efficent surface | m2/m3 | >800 | >900 | >1000 | >800 | >500 |

| Density | g/cm3 | 0.96-0.98 | 0.96-0.98 | 0.96-0.98 | 0.96-0.98 | 0.96-0.98 |

| Packing numbers | pcs/m3 | >630000 | >830000 | >850000 | >260000 | >97000 |

| Porosity | % | >85 | >85 | >85 | >85 | >90 |

| Dosing ratio | % | 15-67 | 15-68 | 15-70 | 15-67 | 15-65 |

| Membrane-forming time | days | 3-15 | 3-15 | 3-15 | 3-15 | 3-15 |

| Nitrification efficiency | gNH3-N/M3.d | 400-1200 | 400-1200 | 400-1200 | 400-1200 | 400-1200 |

| BOD5 oxidation efficiency | gBOD5/M3.d | 2000-10000 | 2000-10000 | 2000-10000 | 2000-10000 | 2000-10000 |

| COD oxidation efficiency | gCOD5/M3.d | 2000-15000 | 2000-15000 | 2000-15000 | 2000-15000 | 2000-15000 |

| Applicable temperature | ℃ | 5-60 | 5-60 | 5-60 | 5-60 | 5-60 |

| Life span | year | >15 | >15 | >15 | >15 | >15 |

![[Copy] High Performance Tower Packing Plastic Hiflow Ring](https://cdn.globalso.com/ztaipacking/Plastic-Hiflow-Ring2-300x300.jpg)