Cordierite-Mullite Honeycomb for RTO/RCO | Advanced Thermal Storage Media

Mullite-Cordierite Honeycomb Ceramic for RTO/RCO Systems

As the core component of High Temperature Air Combustion (HTAC) systems, our honeycomb ceramic thermal storage media delivers

exceptional performance through its unique material properties. Engineered with low thermal expansion coefficient, high specific

surface area, excellent thermal stability, and superior corrosion resistance, this advanced ceramic solution ensures reliable

operation in demanding industrial environments.

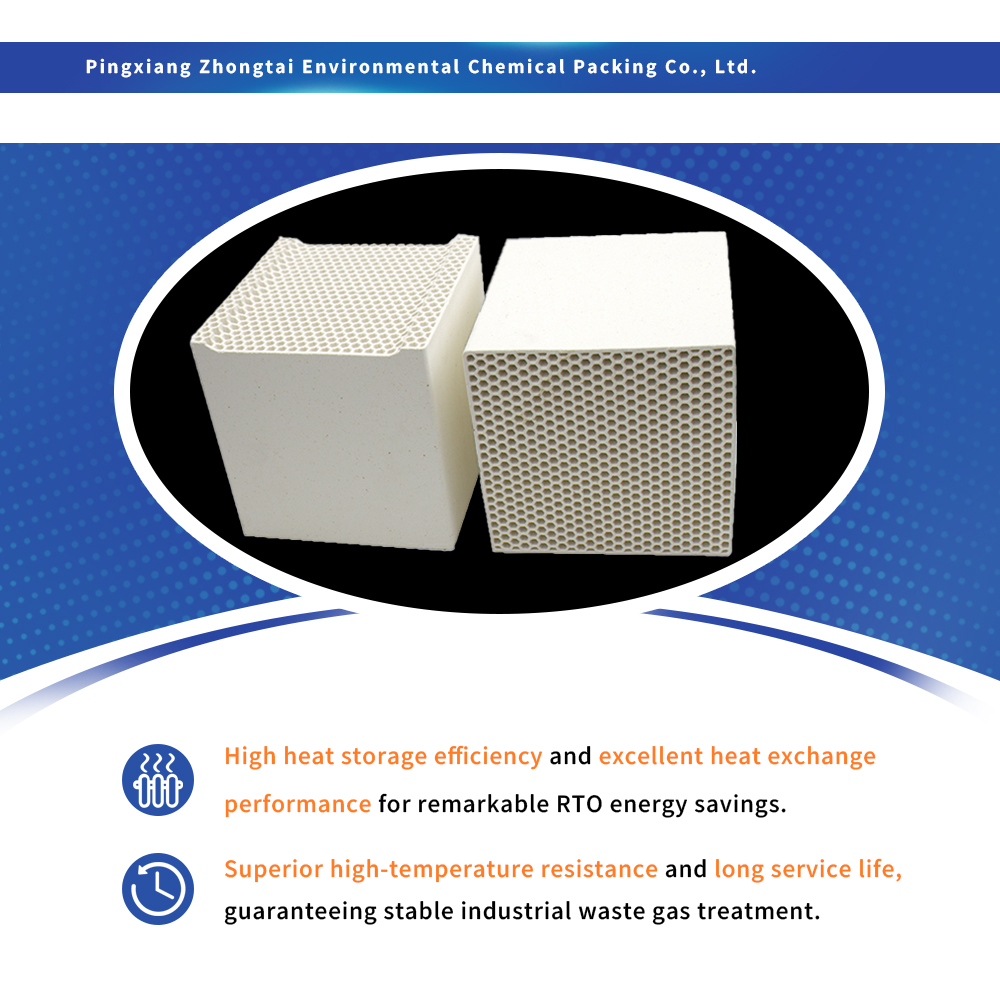

Key Advantages:

* Exceptional thermal shock resistance* High heat storage capacity per unit volume

* Optimized geometric surface area for efficient heat transfer

* Superior mechanical strength and durability

* Excellent resistance to chemical corrosion

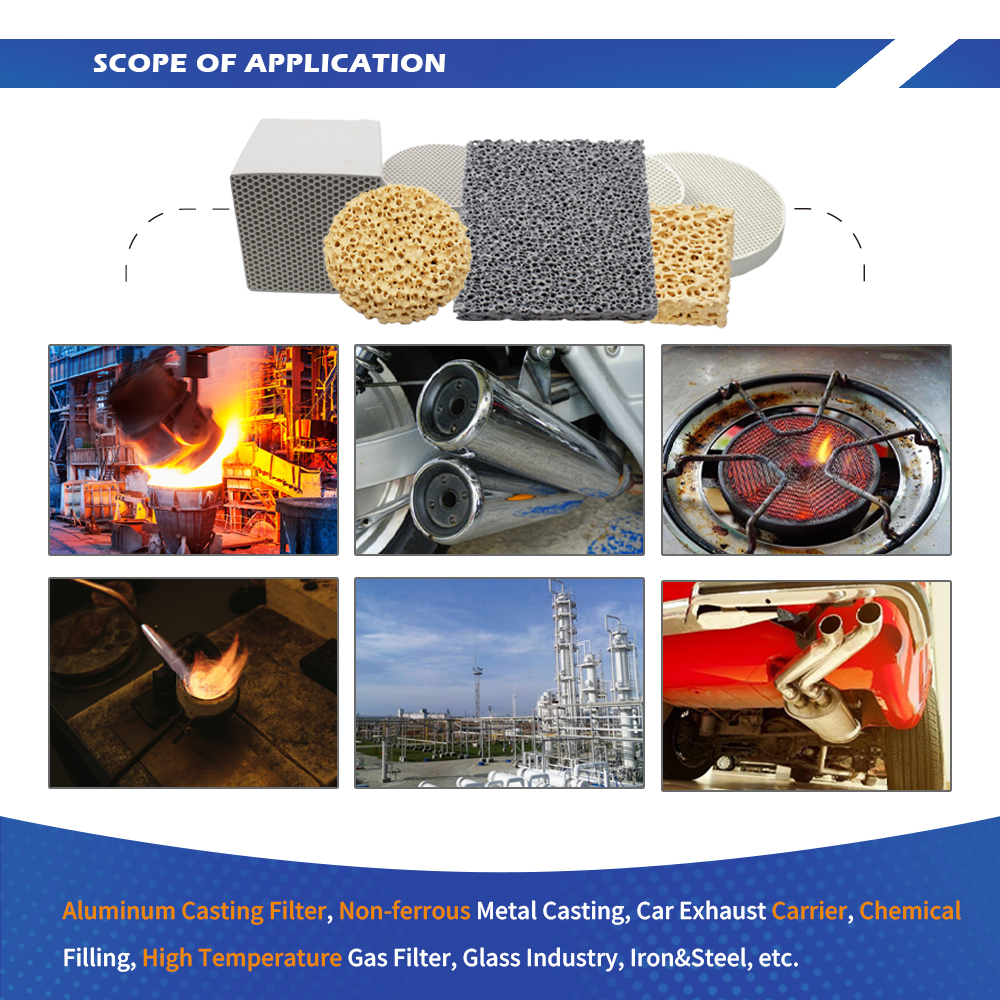

Global Applications:

Our honeycomb ceramics have been widely adopted in RTO (Regenerative Thermal Oxidizer) and RCO (Regenerative Catalytic Oxidizer)

systems across international markets, providing effective VOC abatement solutions for various industrial sectors including

chemical processing, painting, printing, and pharmaceutical manufacturing.

Material Specifications:

We offer comprehensive material options including:

* Mullite-cordierite composite

* High-alumina porcelain formulations

* Corundum-mullite compositions

* Premium cordierite series

* Customized material development

Technical Excellence:

With over 10 specialized honeycomb ceramic formulations developed according to US and European standards, our products ensure:

* Stable operation under thermal cycling conditions

* Long service life with minimal maintenance

* Cost-effective VOC treatment solutions

* Compliance with international environmental regulations

Quality Assurance:

All honeycomb ceramics undergo rigorous quality control and are certified to meet international performance standards,

guaranteeing consistent performance in your RTO/RCO applications.

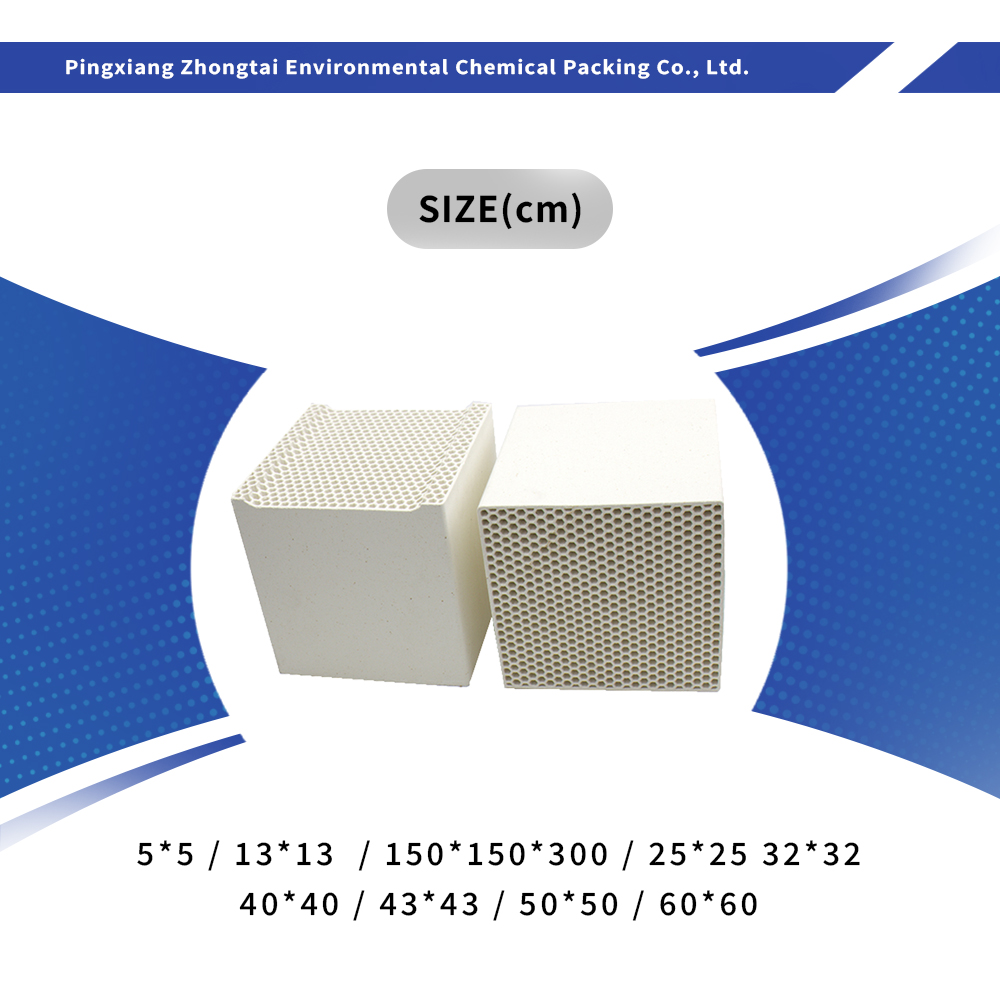

RTO/RCO honeycomb ceramics Main Size:

| L*W*G(mm) | 150x 150 x 300(150) | ||||

| Number of Cell | 25x25=625 | 40x40= 1600 | 43x43=1849 | 50x50=2500 | 60x60=3600 |

| Width of Cell(mm) | 4.95 | 3.02 | 2.81 | 2.38 | 1.98 |

| Thickness of inner wall(mm) | 1.0 | 0.7 | 0.65 | 0.6 | 0.5 |

| Surface Area(m2/m3) | 577 | 886 | 950 | 1084 | 1294 |

| Opening Ratio(%) | 68 | 65 | 65 | 63 | 63 |

RTO/RCO honeycomb ceramics Chemical composition:

| Item | Aluminum Porceian-cordierite | Dense aluminum porcelain | Cordierite | Mullite-Cordierite | Mullite | Enamel |

| SiO2 | 25~35 | 25~35 | 45~55 | 40~50 | 25~35 | 68~72 |

| Al2O3 | 55~65 | 55~65 | 28~38 | 55~65 | 55~65 | 22~26 |

| MgO | 2~4 | 2~4 | 11~14 | 5~9 | ≤2 | ≤0.5 |

| Fe203+TiO2 | 1~4 | 1~4 | 1~3 | 1~3 | 1~4 | 1~3 |

| Others | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

| Thermal shock resistance Max Temperature(℃) | ≥400 | ≥300 | ≥450 | ≥350 | ≥350 | ≥300 |

| Advised Max Temperature(℃) | 1250 | 1350 | 1150 | 1250 | 1450 | 1200 |

| Water Absorption Rate(%) | ≤20 | ≤5 | ≤22 | ≤20 | ≤20 | ≤10 |

RTO/RCO honeycomb ceramics Physical Properties:

| Item | Aluminum Porceian-cordierite | Dense aluminum porcelain | Cordierite | Mullite-Cordierite | Mullite | Enamel |

| Density(g/cm3) | 2.0~2.3 | 2.4~2.6 | 1.6~1.9 | 1.7~2.0 | 2.0~2.4 | 1.7~2.0 |

| Bulk density (g/cm3) | 0.65~0.8 | 0.65~0.8 | 0.6~0.7 | 0.65~0.75 | 0.65~0.8 | 0.65~0.75 |

| Thermal Expansion Coefficient (X10-6°C-1) (RT-800°C) |

≤6 | ≤6 | ≤3 | ≤3.5 | ≤5.5 | ≤6.5 |

| Specific heat capacity (J/Kg.k) |

950~1150 | 1000~1200 | 900~1100 | 900~1100 | 1000~1150 | 900~1100 |

| Thermal Conductivity (w/m.k)(20-1000°C) | 1.5~2.0 | 1.5~2.0 | 1.2~1.8 | 1.4~1.9 | 1.5~2.0 | 1.4~1.9 |

| Thermal shock resistance Max Temperature(℃) | ≥400 | ≥300 | ≥450 | ≥350 | ≥350 | ≥300 |

| Advised Max Temperature(℃) | 1250 | 1350 | 1150 | 1250 | 1450 | 1200 |

| Water Absorption Rate(%) | ≤20 | ≤5 | ≤22 | ≤20 | ≤20 | ≤10 |