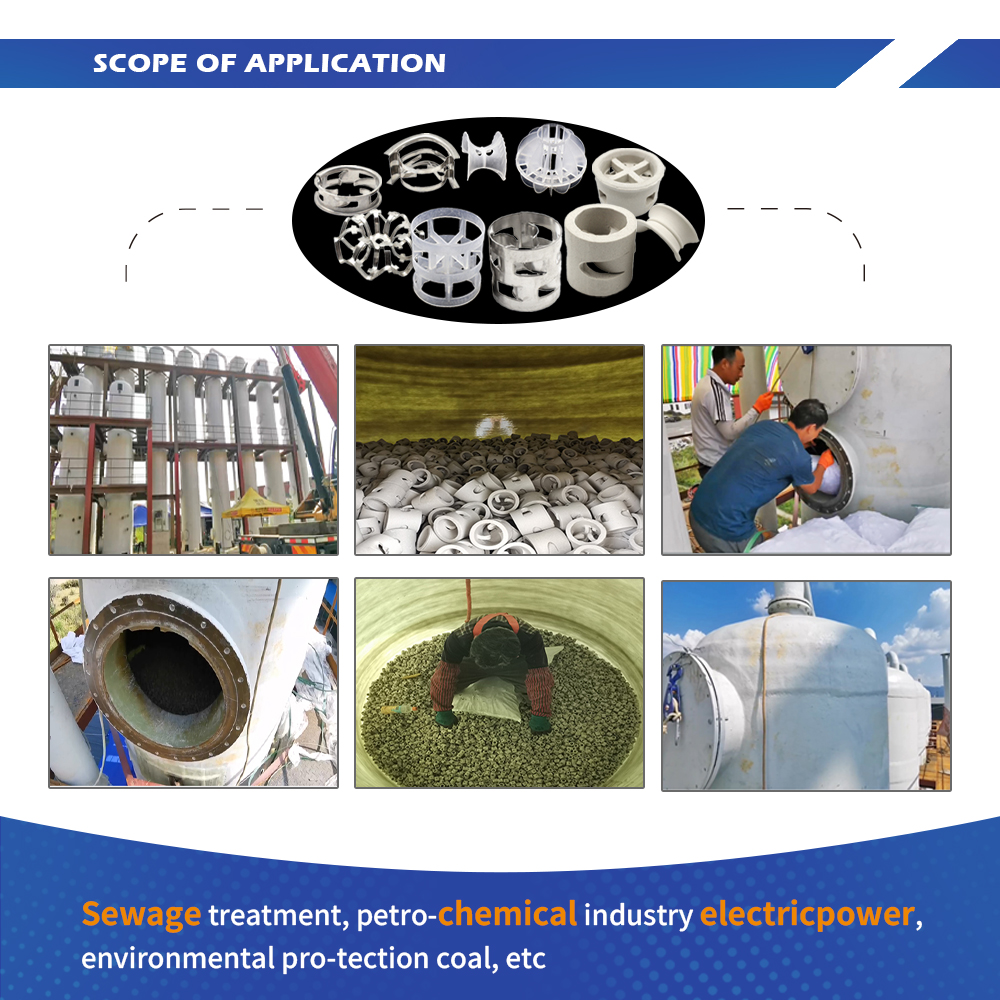

Ceramic Raschig Ring – Random Tower Packing for Absorption, Distillation & Industrial Processing Towers

Introduce:

Raschig Rings are an excellent distillation column filling due to their extremely high surface area and consistent, defined large void space. A benefit of using Raschig Rings as distillation column packing is that they are an inert type of packing so you don't have to worry about packing the column too tightly, which can cause choking.

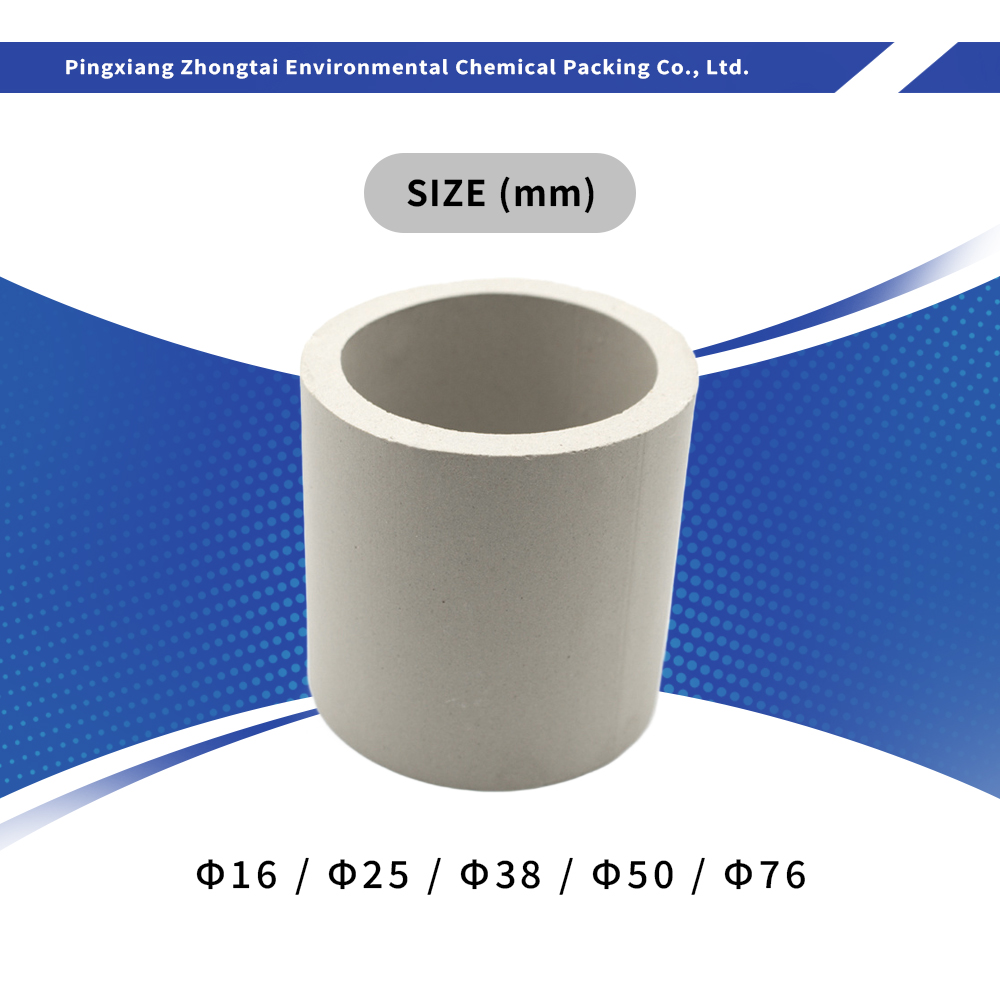

Ceramic raschig ring is one of the earliest developed random packing, the structure is simple, the height and diameter are the same. Raschig rings large size (100mm or more) means the general rules by filling the entire puzzle, 90mm size raschig rings generally use the following method loading number.

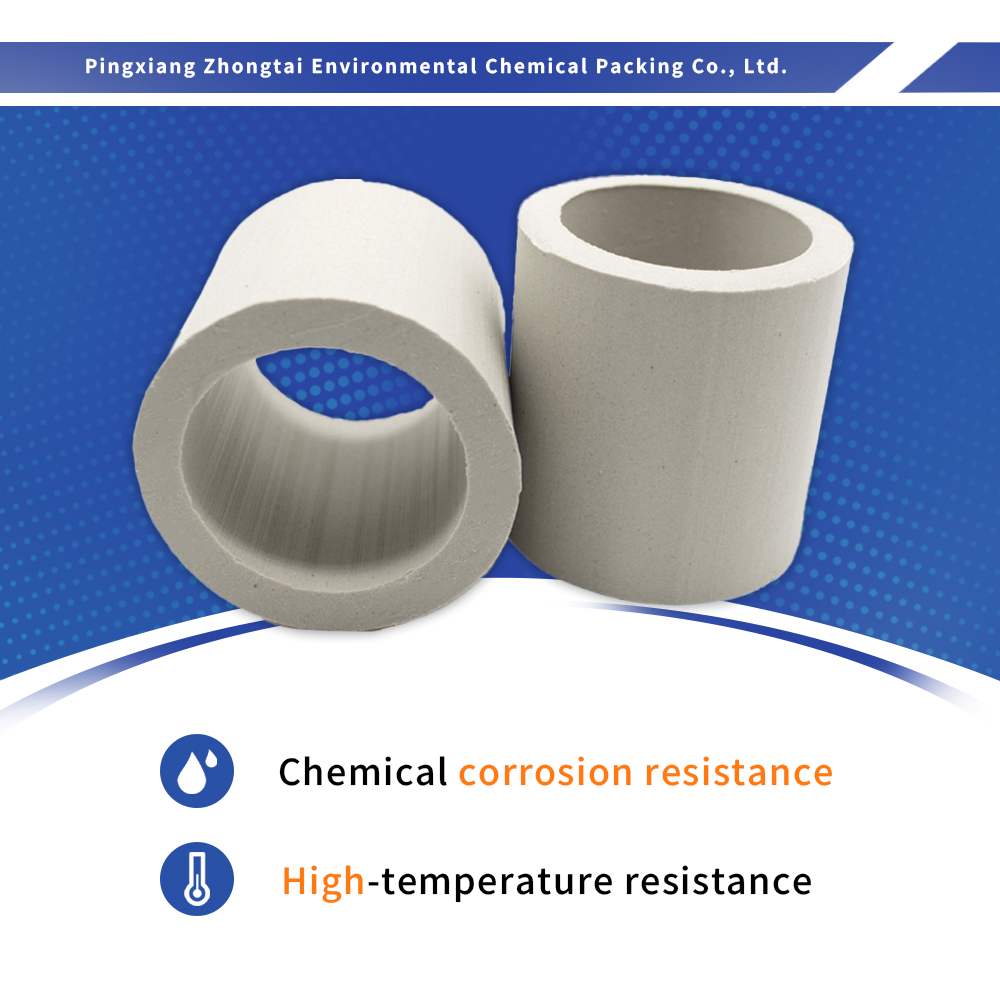

Advantage:

It has the characteristics of excellent acid resistance and heat resistance. It can resist to corrosion of various inorganic

acids, organic acids and organic solvents except hydrofluoric acid, and can be used in high or low temperature conditions,

It has the characteristics of excellent acid resistance and heat resistance. It can resist to corrosion of various inorganic

acids, organic acids and organic solvents except hydrofluoric acid, and can be used in high or low temperature conditions,

| SiO2 | Al2O3 | Fe2O3 | CaO | K2O+Na2O |

| >70% | 23-30% | <1% | <1-2% | <2-4% |

Physical properties

| Index | Value |

| Specific gravity(g/cm3) | 2.25-2.35 |

| Water absorption(%) | <0.5 |

| Acid-resisting strength, %Wt. Loss (ASTMc279) | <4 |

| Firing temperature(Degree C) | 1280-1320 |

| Softening point(Degree C) | >1400 |

| Density(kg/m3) | 2350 |

|

||||||||||||||||||||||||||||||||||||

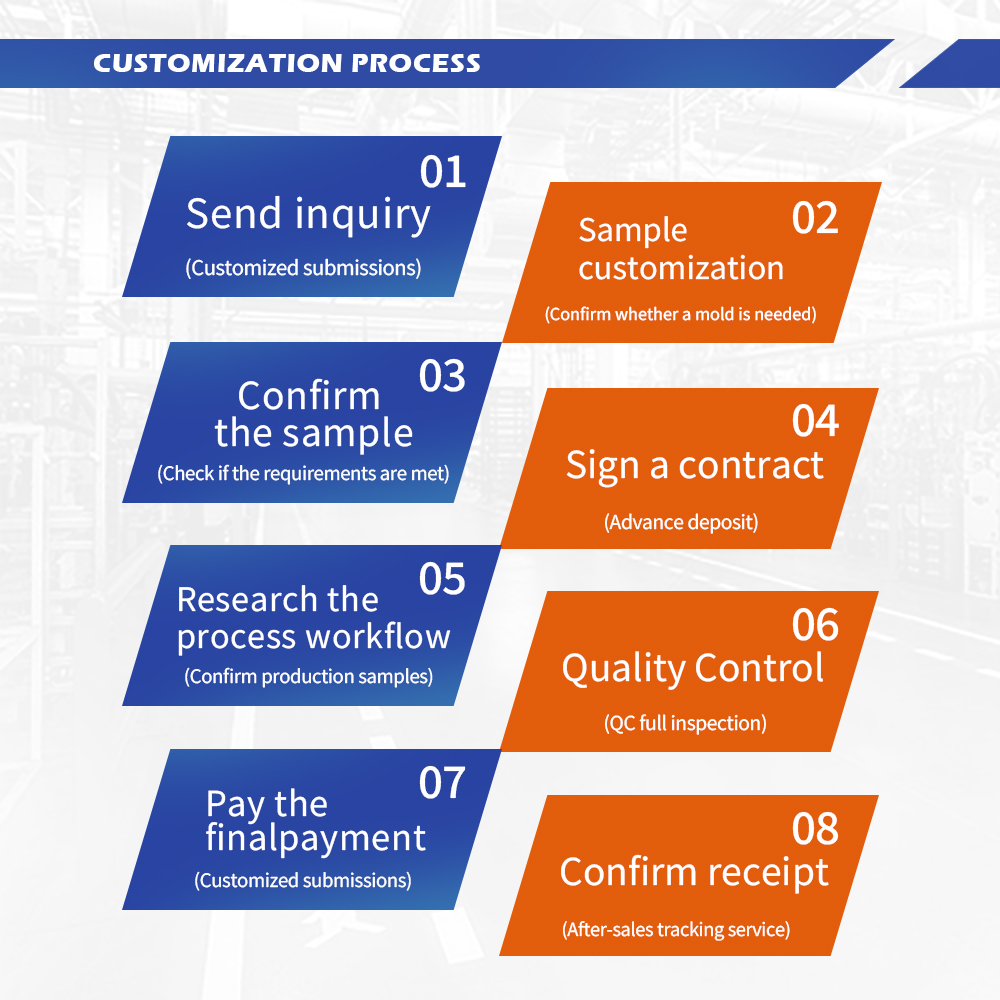

Write your message here and send it to us

-300x300.jpg)

.jpg)