400 CPSI Cordierite Heater Plate | High-Temp Infrared Industrial Heater

Product Overview

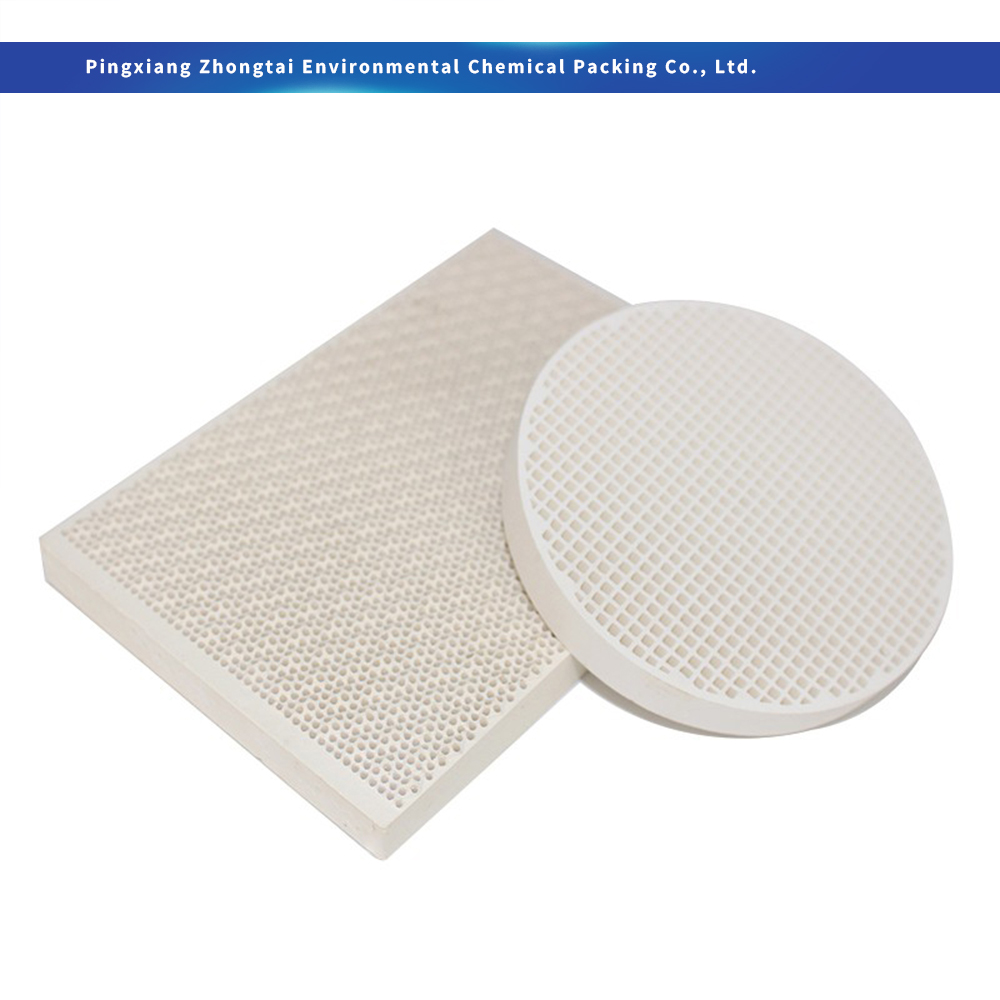

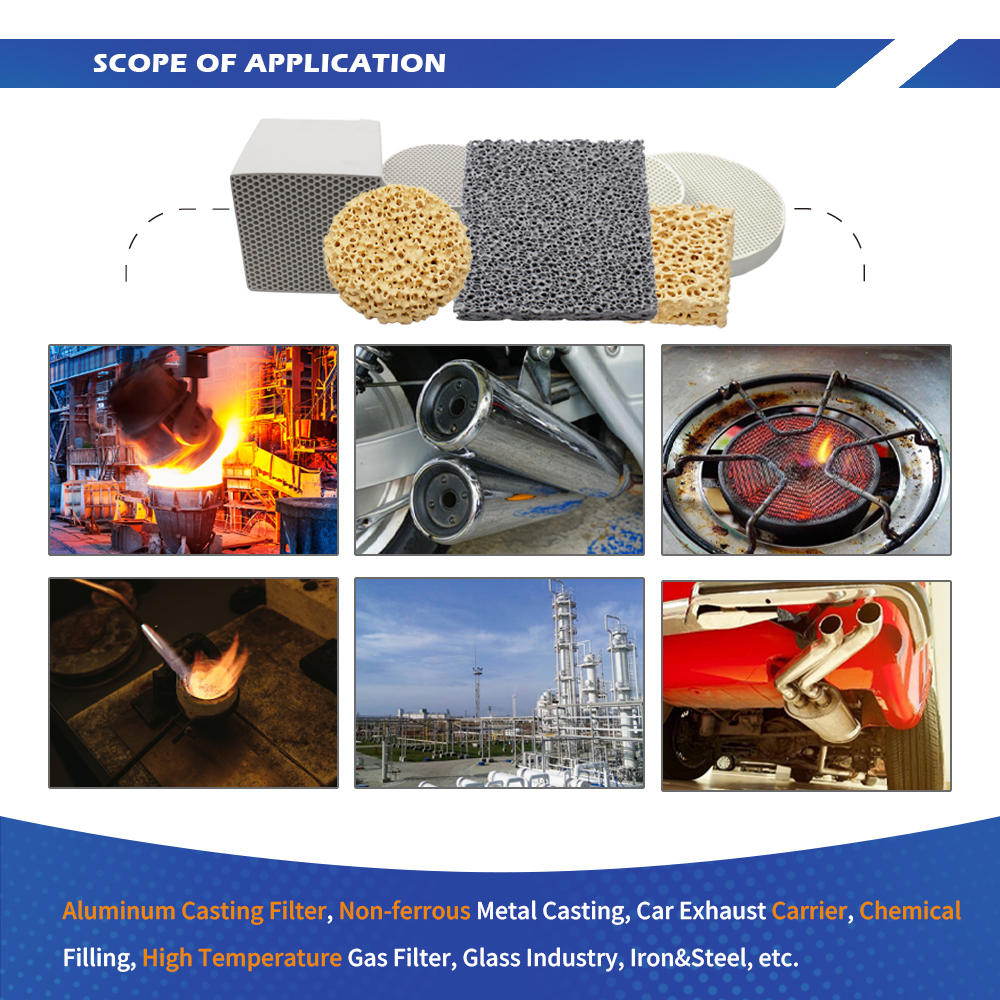

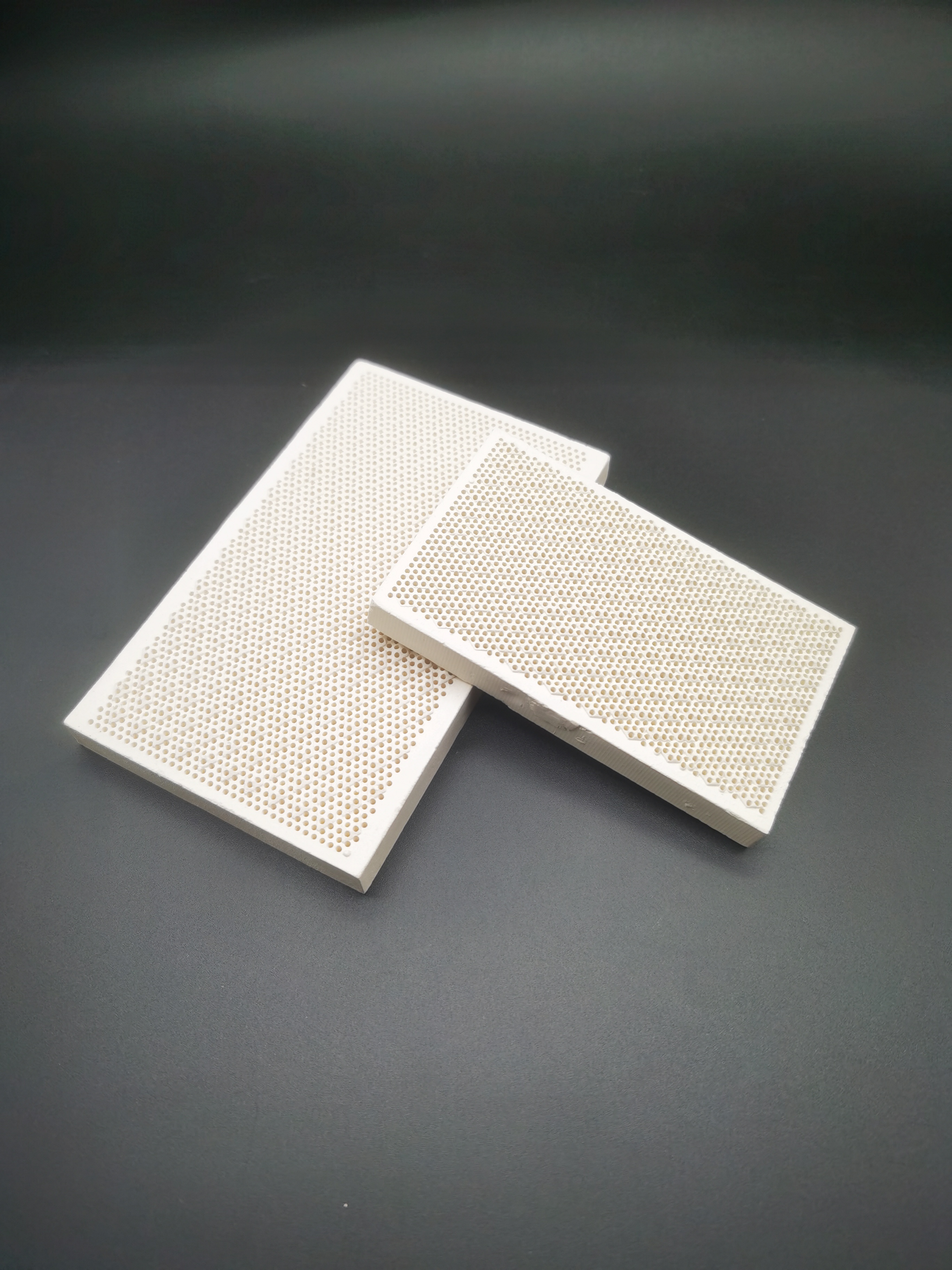

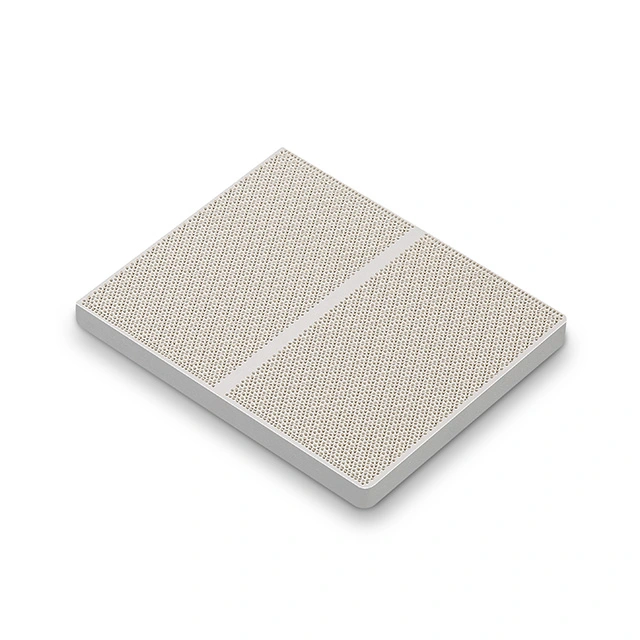

The Ceramic Honeycomb Plate is a high-performance industrial component featuring a porous cellular structure. It is renowned for its exceptional thermal conductivity, high-temperature stability, and corrosion resistance. Manufactured from advanced ceramic materials such as cordierite and mullite, it is precision-formed into a honeycomb configuration that significantly increases the effective surface area. This design enables efficient heat transfer and uniform fluid distribution, making it ideal for industrial heating, exhaust treatment, energy recovery, and catalytic processes. It serves as a reliable solution for improving energy efficiency and reducing emissions.

Key Advantages

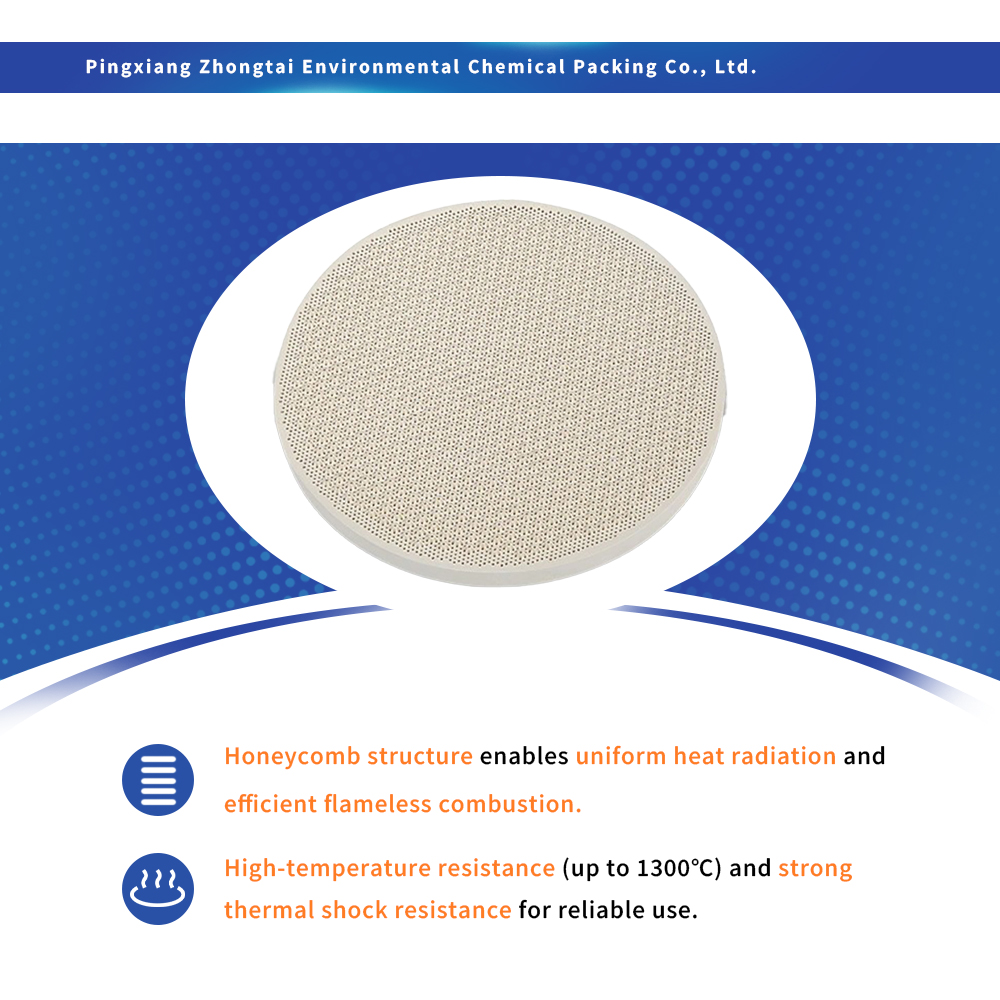

* Efficient Thermal Management: The honeycomb structure ensures even heat distribution and a rapid thermal response, leading to lower energy consumption.

* Excellent Stability: It withstands extreme temperatures and thermal shock while maintaining structural integrity under demanding conditions.

* Strong Corrosion Resistance: This component resists chemical erosion from acids, alkalis, and oxidizing environments, ensuring long-term durability.

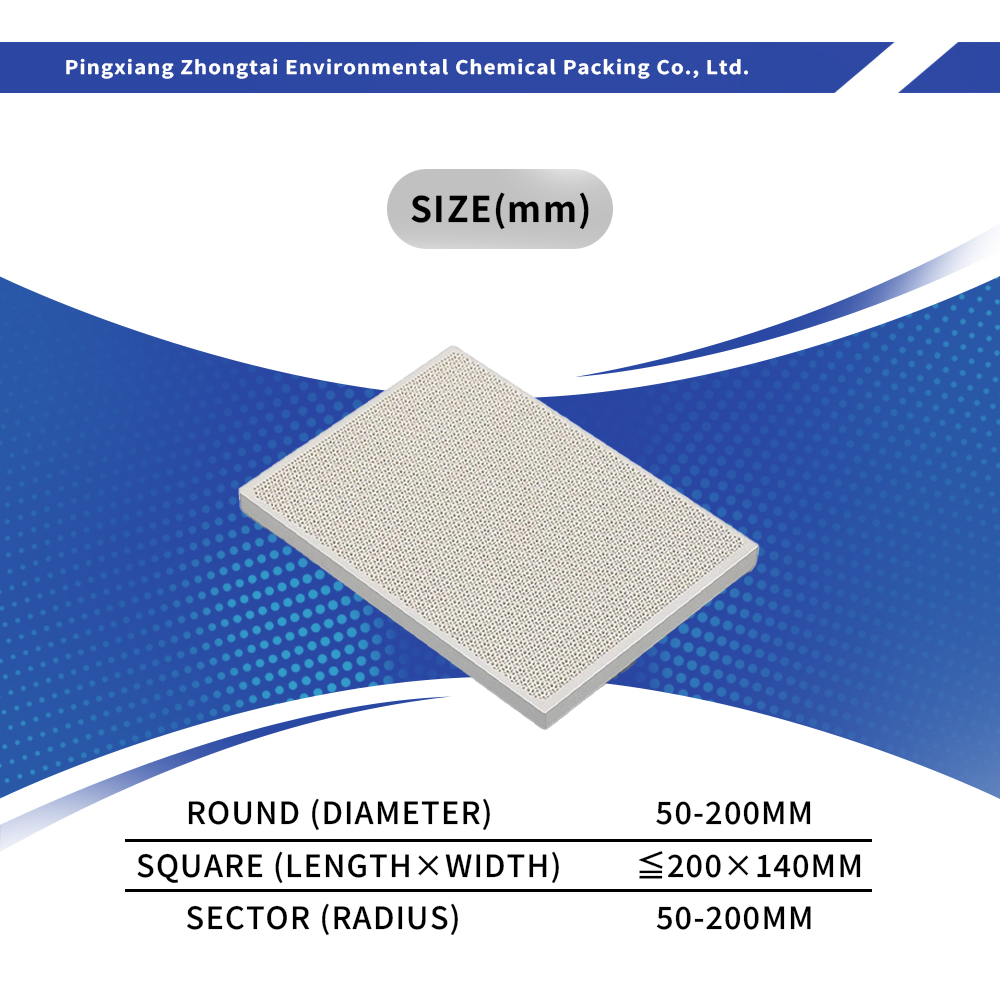

* Customization Flexibility: We support tailored specifications in cell density, size, and shape to meet diverse application

requirements.

* Energy Saving & Eco-Friendly: The design promotes complete fuel combustion and reduces harmful emissions such as NOx.

| Ceramic material performance index | |||||

| Alumina Ceramic | Zirconia Ceramic | ||||

| Performance | Unit | ≧95 | ≧99 | ≧99.5 | |

| Bulk density | g /cm3 | 3.7 | 3.85 | 3.85 | 6 |

| Hardness | HRA ≥ | 86 | 88 | 88 | 92 |

| Flexure strength | Mpa≧ | 300 | 350 | 400 | 1100 |

| The max.temperature | ℃ | 1500 | 1500 | 1500 | 1450 |

| Linear expansion coefficient | ×10-6/℃ | 7.5 | 8.2 | 8.2 | 10.2 |

| Dielectric constant | εr20℃, 1MHz | 9 | 9.2 | 9.2 | 28 |

| Dielectric loss | tanδ×10-4, 1MHz | 3 | 2 | 2 | 10 |

| Volume resistivity | Ω·cm 20℃ | 10^13 | 10^14 | 10^14 | 10^14 |

| Disruptive strength | KV/mm , DC≥ | 20 | 20 | 20 | 20 |

| Acid resistance | mg/cm2 ≤ | 0.7 | 0.7 | 0.7 | 2 |

| Alkali resistance | mg/cm2 ≤ | 0.2 | 0.1 | 0.1 | 0.08 |

| Abrasive resistance | g/cm2 ≤ | 0.2 | 0.1 | 0.1 | 0.05 |

| Compressive strength | MPa ≥ | 2500 | 2500 | 2500 | 3000 |

| Rupture strength | MPa ≥ | 200 | 350 | 350 | 600 |

| Elasticity modulus | GPa | 300 | 350 | 350 | 210 |

| Poisson ratio | 0.2 | 0.22 | 0.22 | 0.23 | |

| Heat conductivity | W/m·K( 20℃) | 20 | 25 | 25 | 2.6 |